Excitement About Digital Printing

Table of ContentsThe Facts About Digital Printing RevealedThe Buzz on Digital PrintingThe Single Strategy To Use For Digital PrintingDigital Printing Can Be Fun For EveryoneUnknown Facts About Digital PrintingThe Ultimate Guide To Digital PrintingLittle Known Questions About Digital Printing.The Best Strategy To Use For Digital Printing

Modification additionally permits companies to stick out in a jampacked market by creating unique advertising products that differentiate them from their competitors. Among the main benefits of digital printing is the capacity to print variable data. Each published piece can be one-of-a-kind, allowing businesses to produce tailored advertising and marketing products that speak straight to their target market.Digital printing additionally permits for customization in the design of marketing materials. With electronic printing, businesses can produce layouts that are one-of-a-kind and customized to their certain requirements. This can include customized graphics, fonts, and layouts that can assist to distinguish them from their rivals. An additional advantage of digital printing is the capability to print as needed.

6 Easy Facts About Digital Printing Shown

By printing smaller quantities of advertising products, companies can lower waste and stay clear of the demand for excess inventory. Digital printing is also versatile.

By using various products and styles, organizations can produce unique advertising products that stand out from their rivals and attract focus from their target audience. Digital printing likewise provides consistency. With conventional printing techniques, there is often variation between prints due to distinctions in ink coverage, stress, and various other factors.

This consistency can aid construct client depend on and integrity, revealing that business is committed to giving high-quality materials. Consistency is particularly important for companies that want to build customer depend on and credibility. By guaranteeing that every print corresponds, companies can show that they are dedicated to offering high-quality products and focusing on the details.

Excitement About Digital Printing

Additionally, electronic printing generates less waste since it can print on demand and in smaller amounts, lowering the requirement for excess inventory and materials. Digital printing likewise utilizes much less power compared to traditional printing techniques. Digital printers do not call for as much energy to run, as they do not need to warm up as much or use as much power to run.

Getting My Digital Printing To Work

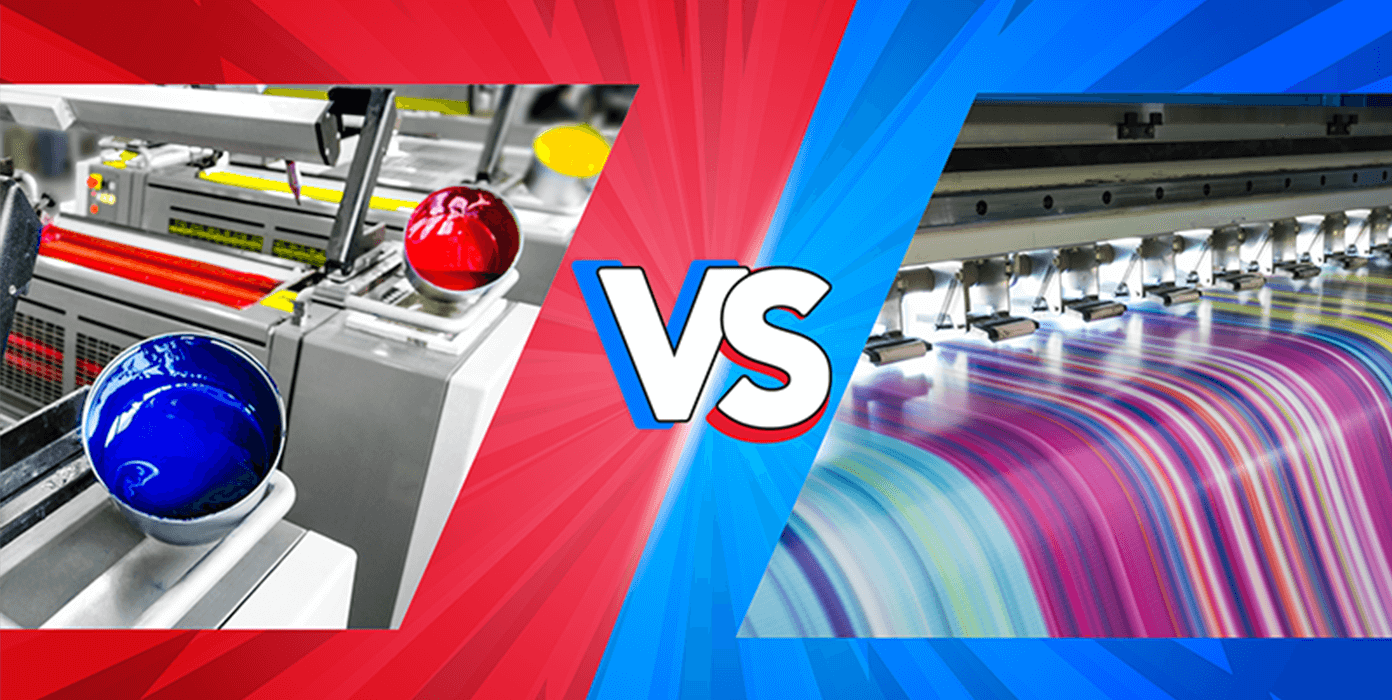

Balanced out printing calls for a plate for each shade published. Typical countered printing is a print method that makes use of light weight aluminum plates to transfer ink onto a rubber sheet (commonly referred to as see this here a "covering").

A Biased View of Digital Printing

Countered printing allows for a wide array of print products to be utilized during production. The premium photos produced via balanced out printing make it the preferred approach, especially among visuals developers, when looking for the biggest color recreation, detail, and professional-looking prints.

For electronic inkjet printing, ink is transferred straight onto the surface area. Rather than counting on aluminum plates and rubber coverings to move a picture, digital printing uses fluid ink throughout manufacturing.

Getting The Digital Printing To Work

Since countered printing can mix customized color inks for each job, it will naturally get the shades spot-on. Count on offset printing for clean, distinctive kinds and photos without touches or places.

It sets you back a great deal to start an offset other task. You need to spend money right into producing the plates, which takes some time. However, as soon as you've invested it, every one of the products prepare to go, and you'll invest less on big countered work than an electronic print, which has to do with the same per item no issue how big the work obtains.

Each print is the same. You take the chance of less odd variations triggered by inequalities in water and ink. Digital printing is much less costly for low-volume tasks. The cost each drops for electronic printing, so at some point, they crisscross. Altering information within a solitary print work. For example, claim you were printing out postcards promoting a show.

Digital Printing Fundamentals Explained

While electronic printing or inkjet printing is the recommended selection in the existing times, there are engaging reasons to convert from offset to electronic printing systems. When publishing countered or electronically, critical choices and procedures are entailed in shade matching.

Whichever the case, the color will certainly require to be matched. Color matching of digital printer ink is no more challenging with dyes and pigments. Industrial inkjet printing offers flexibility for printing on various substratums. Digital printing is ideal for consumers that do not need longer runs and warehousing products.

One benefit of electronic printing is choosing from a large array of electronic substratums. With electronic printing, the cost of the substrate in the overall task is small.

How Digital Printing can Save You Time, Stress, and Money.

drop-on-demand is the 2nd printing innovation to think about. Continual inkjet systems go to my site need considerable maintenance, more operator training, and greater downtime. Nonetheless, equipment expenses in inkjet printing are much reduced than countered printing as there are no plate-making, plates, and press costs. Beyond the resources expense, the prepress tools and printing presses call for extremely proficient operators in offset printing, which includes labor costs.